Automated production lines have become increasingly popular in various industries. The packaging industry specifically has benefited greatly from automated machinery. The newest addition to the automated packaging lineup is the automatic filling capping labeling machine. This machine is capable of completing a series of functions including filling containers, loading caps, screwing caps on tightly, labeling and discharging the finished product. The machine can handle various products, including lotion, cream, and paste, as long as the brand name has been removed.

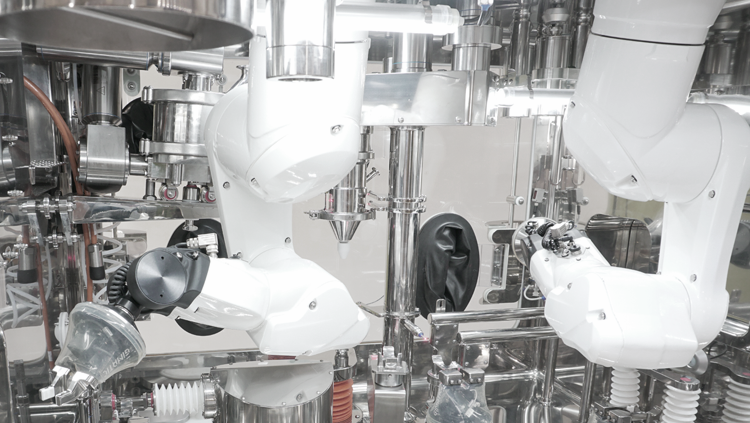

The automatic filling capping labeling machine is a breakthrough technology in the packaging industry. It is equipped with high precision sensors and servo motors that control the filling process, ensuring a consistent level of product in each container. The machine is designed to handle products of varying viscosities, ranging from thin lotion to thick creams and pastes. This capability makes it an ideal solution for manufacturers of cosmetic and personal care products.

The automated capping machine is designed to work with screw-on caps of varying sizes, securely tightening them onto the container. This feature eliminates the risk of spillage during transportation and ensures that the product remains fresh and contamination-free. The machine also has a labeling function that affixes labels onto the containers, providing product information and branding details.

One of the most significant advantages of the automatic filling capping labeling machine is its production efficiency. The machine can fill, cap, and label thousands of containers per hour, significantly reducing labor costs and increasing production capacity. It also increases accuracy, reducing the chances of human error that can lead to product loss. Additionally, the machine has a small footprint, taking up less space on the production line and providing maximum output with minimal investment.

In conclusion, the automatic filling capping labeling machine is a game-changing technology in the packaging industry. Its ability to automate the filling, capping, and labeling process offers manufacturers an opportunity to increase productivity and efficiency while ensuring product consistency and quality. As a manufacturer of cosmetic and personal care products, investing in an automatic filling capping labeling machine could potentially transform your production line, increase efficiency, and improve profits. Keywords such as lotion filling machine, cream filling machine, paste filling machine, automatic filling machine, capping machine, labeling machine, and production efficiency are crucial factors to consider when searching for the right automation solution for your manufacturing needs.