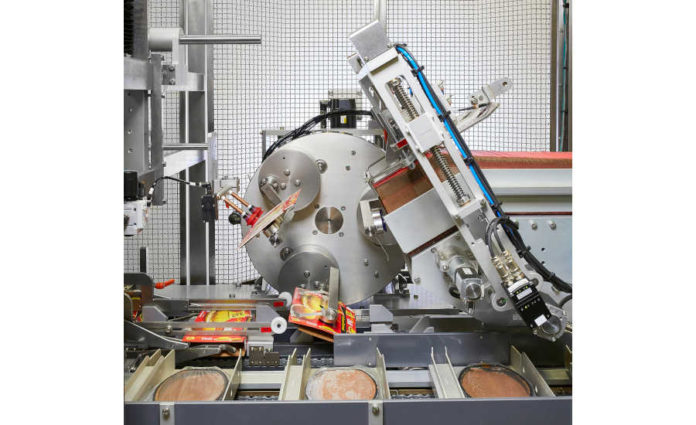

Firstly, what is a horizontal cartoning machine? Simply put, it's a machine that automatically loads products into cartons or boxes that are then sealed and prepared for shipment. This type of machine is ideal for companies that need to package their products quickly and efficiently, as it can handle large volumes of products in minimal time. Horizontal cartoning machines are versatile and can handle a wide range of products including bottles, bags, tubes, cans, jars, and more.

There is a wide range of horizontal cartoning machines available in the market, and they can be categorized into two types: continuous and intermittent motion. Continuous motion machines are designed for high-speed packaging of products. They are ideal for packaging small products such as snack bars, biscuits, and chocolate bars. Intermittent motion machines, on the other hand, are suitable for larger products such as cereals, long goods pasta, and other similar items. These machines work by feeding products into the carton at a slower speed, which allows for more accurate loading and sealing.

The benefits of using a horizontal cartoning machine are numerous. Firstly, it eliminates the need for manual packaging, which saves time and improves efficiency in the production process. Secondly, it ensures that products are loaded into the carton accurately, reducing the risk of damage during transportation. Thirdly, it allows for consistent packaging, ensuring that all products are packaged in the same way every time. Lastly, it helps to reduce labor costs, as it eliminates the need for manual workers to package products.

When choosing a horizontal cartoning machine, there are several factors to consider. One important factor is speed. You need to choose a machine that can handle your product's speed requirements. Another factor to consider is the size of your product. You need to ensure that the machine you choose can handle the size and weight of your product. Additionally, you need to consider the type of carton that you want to use. Some machines are designed for specific carton sizes, so it's important to choose a machine that is compatible with your carton size requirements.

In conclusion, a horizontal cartoning machine is an essential element in any packaging system that handles high volumes of products. It offers speed, efficiency, accuracy, and consistency in the packaging process, and helps to reduce labor costs. When choosing a horizontal cartoning machine, it's important to consider factors such as speed, product size, and carton size. With the right machine, your packaging process can become smoother, faster, and more efficient.